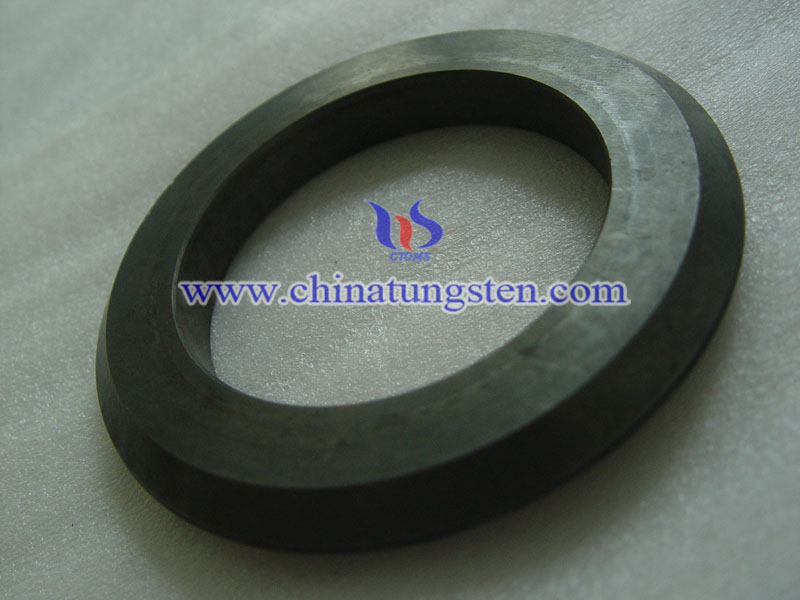

Tungsten Carbide Seals Physical Properties

Tungsten carbide seals are a amount of more hard surface materials during mechanical seal friction , using a wide range, good wear resistance, high flexural strength, high thermal conductivity, low coefficient of expansion, all hardfacing material is the highest coefficient of thermal shock material. Carbide mechanical seal ring is a high hardness refractory metal carbides (WC, TiC) micron powder is the main component and a cobalt (Co) or nickel (Ni), molybdenum (Mo) as the binder in vacuo furnace or hydrogen reduction furnace sintering powder metallurgy products. Besides carbon atom, a nitrogen atom, a boron atom can enter the gap in the metal lattice, is formed between the charge and a solid solution. Tungsten carbide Seals filling a similar nature between carbide and can conductivity, thermal conductivity, high melting point, high hardness, and brittleness is also large.

Tungsten carbide seals physical properties parameters:

| Technical Parameters |

Chemical composition | Density | Hardness | Flexural strength |

Coefficient of linear expansion |

||

| Unit | WC% | Ni% | Co% | g/cm3 | HRA | Mpa | 10-6/K |

| YWN6 | 94 | 6 | 6 | 14.5~14.9 | 88.5 | 1490 | 5.2 |

| YWN8 | 92 | 8 | 8 | 14.4~14.8 | 88 | 1470 | 5.3 |

| YG6 | 94 | - | - | 14.6~15 | 89.5 | 1421 | 5 |

| YG8 | 92 | - | - | 14.5~14.9 | 89 | 1470 | 5.1 |