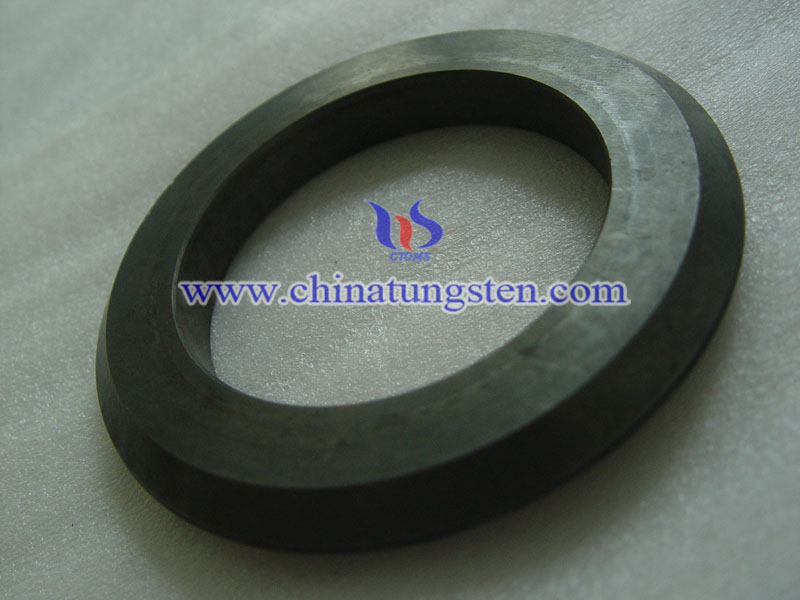

Tungsten Carbide Seals

Mechanical seals including tungsten carbide seals and silicon carbide seals are used increasingly on fluid pump to replace packed gland and lip seal. Pump with mechanical seals perform more efficiently and generally perform more reliably for extended periods of time.

Because tungsten carbide seals are of good wearable resistance, great anti-bend strength, high thermal conductivity, small co-efficient of expansion, they have a very wide range of applications. Tungsten carbide seals also have the highest co-efficient of heat shock among all the hard surface material.

Tungsten carbide seals are extremely tough and stiff and have very good abrasion resistance. Tungsten carbide seals have versatile seal faces like Silicon Carbide. Tungsten carbide seals are very hard like silicon carbide seals; however they are very heavy to the touch, making them easy to distinguish from silicon carbide.

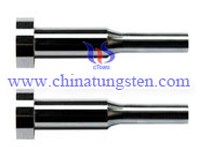

Tungsten carbide seals come in two primary types:

Cobalt bound (Ammonia applications should be avoided)

Nickel bound (May be used in Ammonia)

Typically 6% binder materials are used in mechanical seals, although a wide range is available. Nickel-bonded tungsten carbide seals are more prevalent in the wastewater pump market due to their improved corrosion resistance compared with cobalt bound materials